Moldflow Service

We provide professional engineering design, analysis, manufacturing, and global sourcing services at a low cost and with a quick turnaround.

Moldflow & Casting Analysis

- Filling, Packing, Warpage & Cooling Analysis

- All types of mold design and optimization

CONTACT US FOR FREE QUOTE

Email: [email protected]

Phone: 1-240-421-0756

Fax: 1-866-304-9034

Address: 15720 Brixham Hill Ave. Suite 300, Charlotte, NC USA 28277

What is the Moldflow analysis?

- Moldflow analysis is a simulation tool used to optimize the injection molding process of plastic parts. It predicts how plastic flows into a mold, cools, and solidifies, identifying potential defects and ensuring quality and efficiency in the manufacturing process.

- Moldflow includes fill analysis, pack analysis, cool analysis, warp analysis, stress analysis, etc.

Our Mission:

- We provide professional moldflow analysis services on plastic parts and casting simulation on metal parts. Our skilled engineers have over a decade of mold design and analysis experience and could solve your most difficult engineering problems.

What we need to run Moldflow analysis:

- 3D CAD model (.stp, .x_t, Solidworks or any other CAD format files)

- The gate information (size, number and location). Or we could optimize the gate parameters.

- Hot or cold runner, cavity number, etc.

- The material data sheet.

- What are your main concerns from the analysis.

What we provide on Moldflow analysis project:

- A full standard Moldflow analysis report.

- The analysis results include: filling time, clamp force, warpage, weldline, temperature, etc.

- Find out potential tooling design issues and provide modification suggestions.

Our Engineering Services

nonlinear, thermal, impact, fatigue, etc.

transient, multiple stream, heat transfer.

injection, gas assist, blow mold, casting.

2D/3D draft, conversion, rendering, etc.

prototype test, material analysis, etc.

3D printing, CNC, casting, injection, etc.

Area Of Expertise

We are expertise in simulation of plastic injection molding and metal casting molding

Filling and Packing Analysis

Warpage and shrinkage analysis

Cooling Analysis and Design

Injection, Gas Assist & Blow Molding

Multi-Component Molding Analysis

Over-Mold Analysis

Insert Mold Analysis

Casting Simulation

Optimize part and mould design

Determine mold design problems

Gate Size & Location Optimization

Optimize process parameters

Optimize heat extraction.

Polymer selection and evaluation

Design for Manufacturing (DFM)

Introduction of Moldflow

Some general concepts and introduction about Moldflow related simulation.

Moldflow analysis is a type of computer-aided engineering (CAE) software that is used to simulate the injection molding process for plastic parts. Moldflow allows engineers to model the flow of plastic materials through the injection molding machine into the mold cavity. The analysis provides insights into how the plastic will fill the mold, how it will cool and solidify, and potential issues such as warpage, sink marks, and air traps.

Key aspects of Moldflow analysis include:

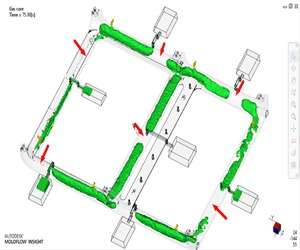

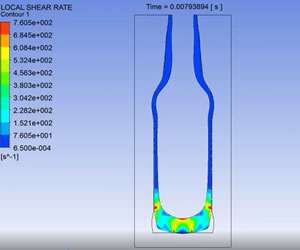

- Fill Analysis: This helps predict the flow pattern of the molten plastic as it fills the mold, identifying potential short shots or air traps.

- Pack Analysis: After filling, additional material is packed into the mold to compensate for material shrinkage as it cools, and this phase of the analysis helps ensure uniform part density and surface quality.

- Cool Analysis: This evaluates how the part and mold cool, which is critical for cycle time estimation and avoiding defects associated with uneven cooling.

- Warp Analysis: It predicts the deformation that might occur due to differential cooling, material properties, and process conditions.

- Stress Analysis: This assesses the stresses within the molded part due to the flow and cooling, which can predict potential issues with part performance.

Overall, Moldflow analysis helps in optimizing the design of the mold and the manufacturing process before actual production begins, saving time and resources by minimizing the number of physical prototypes needed and enhancing the quality of the final product.

- MAGMAsoft: Highly regarded for its robust simulation capabilities, MAGMAsoft is used for optimizing casting designs, processes, and layouts to improve yield and quality.

- SOLIDCast: Known for its user-friendly interface, SOLIDCast is popular among foundries for modeling flow and solidification in casting processes.

- ProCAST: Developed by ESI Group, ProCAST offers comprehensive simulation capabilities for casting, including mold filling, solidification, and casting stress analysis.

- Simufact Casting: A part of the Simufact Engineering suite of tools, Simufact Casting specializes in the simulation of metal casting processes, covering all casting methods and materials.

- Flow-3D Cast: FLOW-3D CAST provides detailed insights into flow patterns and solidification phenomena, with specialized modules for different casting methods.

- NovaFlow&Solid: It is designed to improve the casting yield and quality through simulation by predicting casting defects.

- Material behavior and properties

- Preform shape and thickness distribution

- Air pressure and distribution during the blow phase

- Cooling rate and its impact on the final product

- Autodesk Moldflow: While it is primarily known for injection molding simulation, it also offers capabilities for simulating blow molding processes.

- Simcon Kunststofftechnische Software: This software features specialized tools for blow molding simulation, helping to optimize the production process.

- BlowView from Sigma Engineering: It’s a dedicated tool for blow molding simulations, providing detailed analyses of the entire process.

- Design for Manufacturing (DFM) is a product development approach that emphasizes the importance of designing products for ease of manufacturing. The primary goal of DFM is to simplify the manufacturing process, reducing costs and production time while maintaining product quality.

- It involves considering manufacturing constraints and capabilities during the design phase to ensure that the product can be efficiently mass-produced. By addressing potential production issues early in the design stage, DFM helps eliminate complex, costly, or non-standard components and operations, leading to a more streamlined and cost-effective production cycle.

- It’s a collaborative strategy involving both designers and manufacturers to optimize the product for the manufacturing ecosystem.

Moldflow Project Showcase

Some samples of our completed moldflow related project

Fill & Pack Analysis

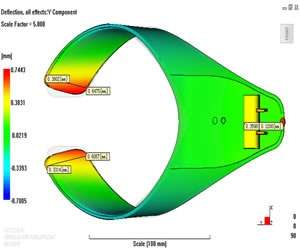

Warpage Analysis

Moldflow Warpage Analysis service is designed to address deformation challenges in plastic injection molding. Leveraging advanced Moldflow technology, we evaluate how factors like material selection, part geometry, and cooling protocols contribute to part warpage. Our insights enable clients to refine mold design and processing parameters, ensuring that the final products maintain dimensional integrity and aesthetic standards. We aid in enhancing the structural and functional quality of molded parts.

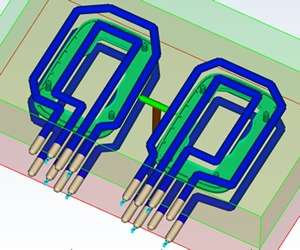

Conformal Cooling Analysis

Cooling Analysis & Design services utilize cutting-edge simulation to revolutionize mold design, enhancing thermal efficiency with tailor-made cooling systems that follow the contour of the mold. This bespoke approach leads to uniform cooling, reduced cycle times, and higher-quality parts with fewer defects. By leveraging our expertise, clients can expect significant improvements in productivity and part longevity. Our service is the bridge between traditional cooling systems and the future of precision thermal regulation in injection molding.

Gas-Assist Injection Analysis

Blow Molding Analysis

Our Blow Molding Analysis services provide a comprehensive simulation of the blow molding process, essential for producing high-quality hollow plastic parts. We meticulously assess parison inflation dynamics, material distribution, and wall thickness consistency. Our advanced analysis pinpoints critical variables impacting the final product’s structural integrity and aesthetics. Clients leverage our expertise to refine mold design, prevent material wastage, and achieve uniform product quality. Ensure blow-molded products are not only durable and functional but also cost-efficient to produce.

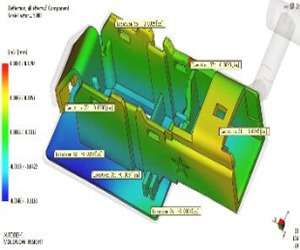

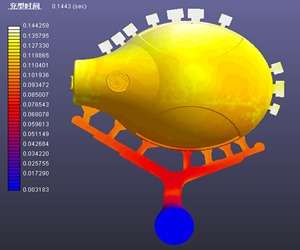

Die Casting Analysis

Our Die Casting Analysis services offer in-depth simulations to streamline the manufacturing of complex metal components. We meticulously evaluate the molten metal flow, solidification, and die temperatures to identify potential defects and optimize gate systems. Our predictive insights help perfect mold designs and refine process parameters, ensuring high-quality castings with minimal porosity and enhanced mechanical properties. Partner with us to elevate the precision and durability of your die-cast products, while minimizing production challenges and maximizing cost-effectiveness.